Concept Submersible 3D Printed By U.S. Navy

3D printing can prove to be a cost-effective resource for militaries across the globe and they have been testing the idea to create replacement parts and even meals for their soldiers. The United States Navy teamed up with the Oak Ridge National Laboratory to 3D print something much bigger than a replacement part. It has 3D printed a submersible as a proof-of-concept in less than four weeks.

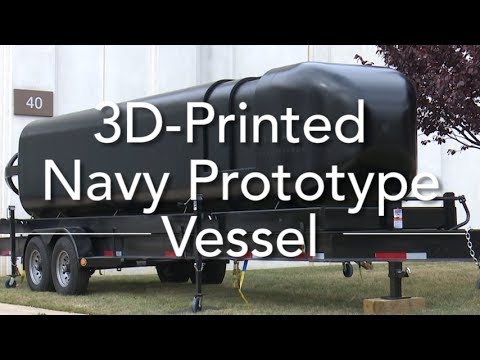

A team from the Naval Surface Warfare Center and Carderock Division’s Disruptive Technology Laboratory developed this 3D printed submersible. It’s called the Optionally Manned Technology Demonstrator and is based on a submersible that the SEALs are currently using.

Work on this project started in August last year and since it’s a pretty big vessel, they had to use an industrial 3D printer called Big Area Additive Manufacturing to print six sections out of carbon fiber. The sections were then assembled to create this 30 foot long vessel.

The team had four weeks to develop the hull so they spent the first week in design and then started printing the components in the following week. It now happens to be the largest 3D printed asset of the United States Navy.

A conventional hull can take up to five months to manufacture and may cost up to $800,000, according to the Department of Energy. This 3D printer hull was 90 percent cheaper and produced in less than a month.

Since this is a proof of concept vessel it’s not functional but it goes to show that it’s indeed possible to print such massive creations. It’s expected that fleet-capable prototypes of the 3D printed vessels could be launched by 2019.

You May Also Like

Popular Right Now

- Canon Unveils PowerShot V1 And EOS R50 V: Best New Vlogging Cameras For 2025

- Bill Gates Predicts: AI Will Replace Doctors And Tutors Within A Decade

- First Shutdown of Niagara Falls in 12,000 Years: A Rare Sight to Behold

- Former Google Engineer claims that humans will achieve immortality soon

- Romotow: The Foldable Camping Trailer Inspired By A USB Flash Drive

- LYRA: Swiss Startup Unveils AR Smart Glasses for Office Work, City Life, And Traveling

- Man Caught in China Smuggling $46K Worth of Intel CPUs Wrapped Around His Waist

- iPhone 15 Pro Max may bring thinner bezels than Xiaomi and Samsung’s latest flagships

- OpenAI's new GPT-4 with a "human-level performance" scored up to 93% on SAT exams

- iPhone SE 4 could be Apple's secret weapon to 'steal' budget customers from Samsung

- Lenovo Launches New Workstations, With Aston Martin DNA

- Ubergizmo’s Best of Mobile World Congress 2023

- TCL NXTPAPER 11 Tablet With Paper-like Screen Experience

- Nothing Phone 2 Coming To The U.S. In Late 2023

- Ubergizmo’s Best Of K-Startup @ CES

- Intel Core i9-13900T Shows Extraordinary Efficiency In Early Benchmarks